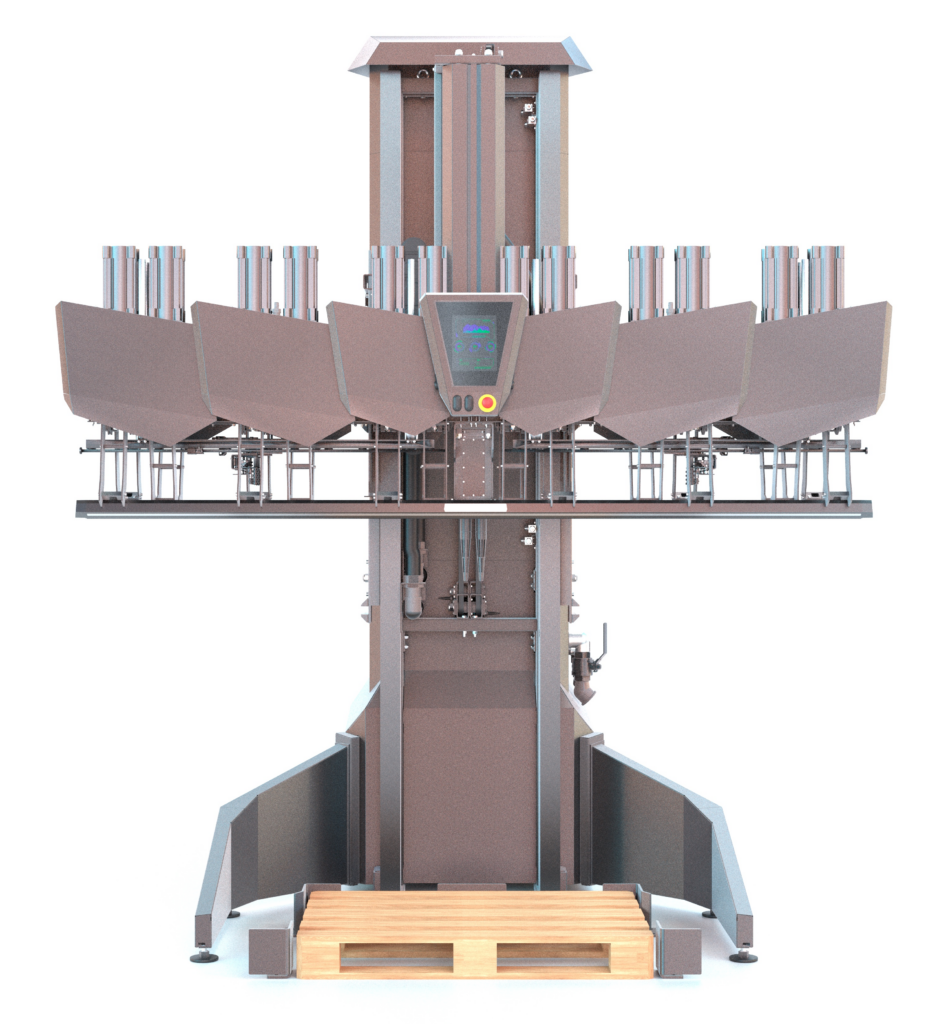

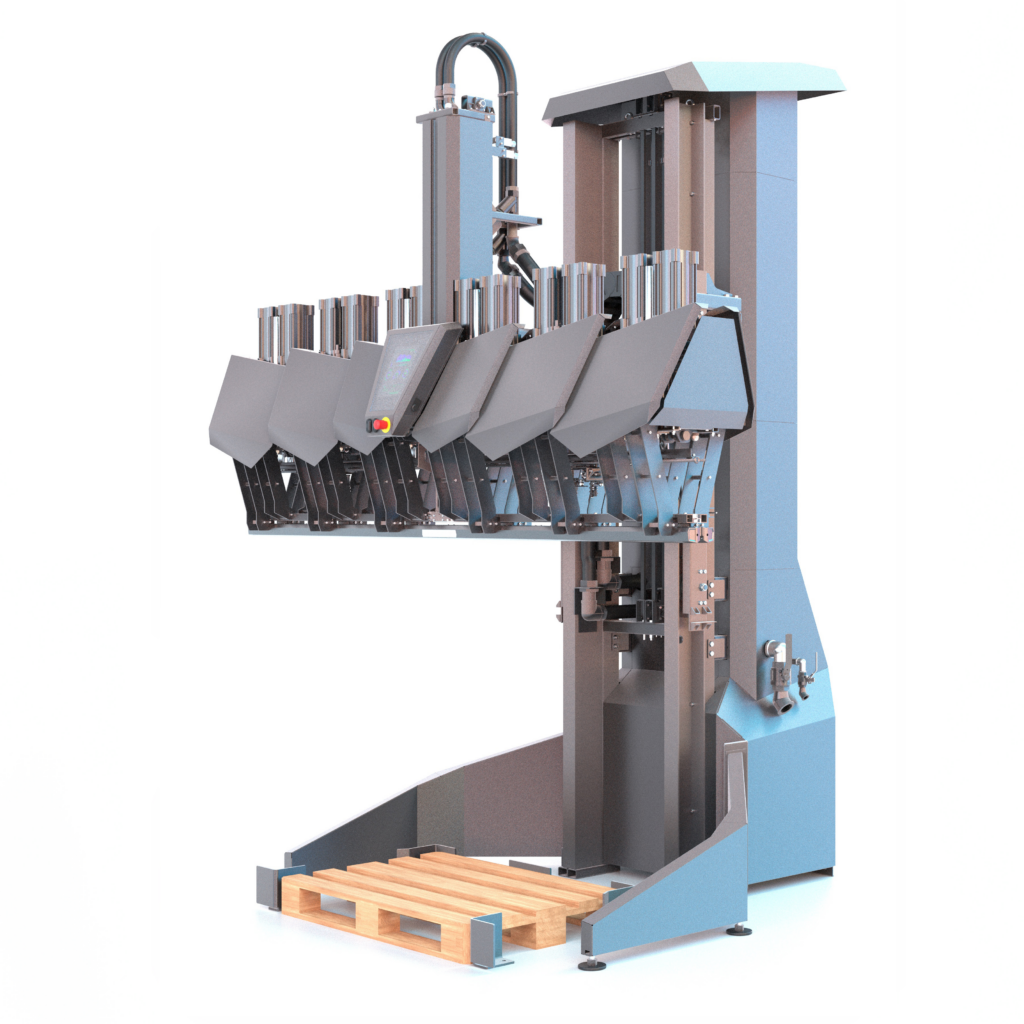

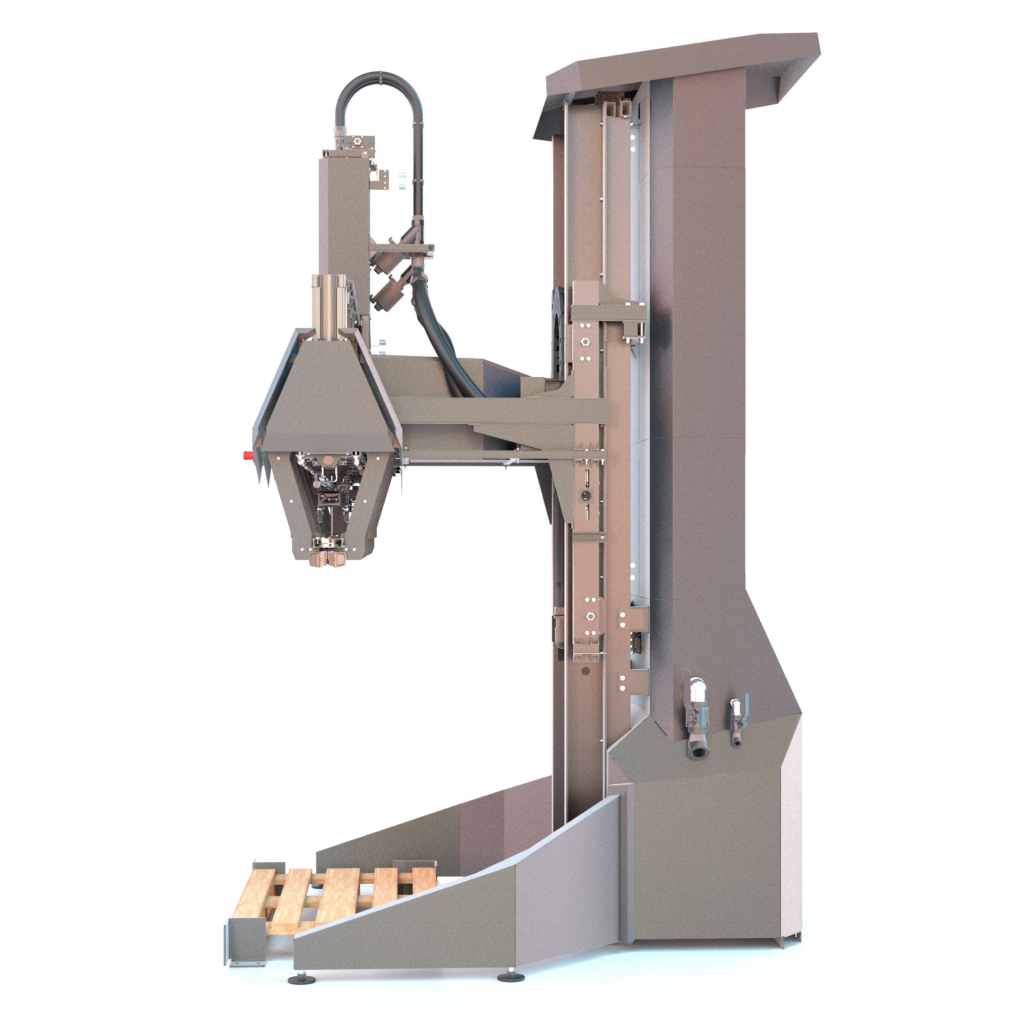

Hacona BI-type

Industrial high performance vacuum sealing machine

My Tasks

Comprehensive mechanical design: concept planning, development, dimensioning, simulations, pneumatic planning

Machine Function and Description

Hacona BI-type machine is a unique, high-performance industrial impulse film sealer with a 2500 mm sealing length, and with vacuum and gas flushing function.

The machine’s application range is extremely versatile, suitable for industrial-scale packaging and preservation of products such as meat, chemicals, pharmaceutical raw materials, food, and raw food industry materials, as well as oilseeds.

The purpose of vacuum/gas packaging is to protect the product from environmental factors such as moisture, oxidation, pests, and UV light.

The machine uses modified atmosphere packaging technology, vacuuming and gas flushing to ensure the ideal air composition inside the packaging material. This low-oxygen environment and controlled gas flushing significantly extend the product’s shelf life. Packaging in large units like Big Bags or pallet-sized crates offers revolutionary efficiency for manufacturers, logistics, and distributors in packaging, storage, and transportation between industrial facilities.

What makes this machine different from other similar industrial solutions?

Hacona BI-type machine is unique in its industry. Hacona Ltd. has been continuously developing the technology it has pioneered for over 15 years, optimizing it for increasingly diverse applications. The Hacona BI-type machine is a versatile dedicated tool.

Unique technology within the industry:

Innovation: External surfaces of vacuum and gas pipes can be sterilized with UVC light.

Innovation: Equipped with a tube washing system. The entire vacuum and gas pipes can be sterilized with disinfectant fluid.

Innovation: Fine filter insert built into vacuum and gas pipes. Enables packaging of dusty products down to 20 microns particle size.

Innovation: Exceptionally long vacuum/gas pipes. Enables vacuuming and gas flushing of large bags without clogging the pipes.

Innovation: Insulated vacuum and gas pipe sealing. Specifically developed vacuum/gas pipe seals hermetically seal the airspace inside the packaging material from the external environment.

Innovation: Validatable according to DIN EN ISO 11607-1:2014 and DIN EN ISO 11607-2:2014. (GMP qualification/validation documentation package)

Innovation: Complete cycle monitoring and individual data backup specifically equipped.

Innovation: Combined cycle possible. Utilizes both vacuum/gas pipe technology and vacuum valve technology.

What industrial need prompted the creation of the machine, and what problem does it solve?

Industrial users want to package products in large-volume “Big Bag” sacks safely, oxygen-free, and as sterile as possible. They need a solution that can easily integrate into their own production lines, is easy to clean, and convenient to handle.

The primary goal was to enhance food safety and extend shelf life, particularly in the food industry. There was a lack of solutions for packaging large-volume units with high-performance and validatable processes. Among packaging machines, there was no combination machine available capable of sealing with a 2500 mm length, accommodating product-specific modified atmosphere packaging with the listed innovative developments.

The sealing of packaging material is carried out with Bi-Activ (dual-sided sealing jaws) developed and continuously improved by Hacona Ltd. for over 15 years. These jaws ensure perfect sealing for materials ranging from 20 to 1400 microns thickness, using any thermoplastic (heat-sealable) packaging material with a melting point between 70 to 260 degrees Celsius.

All machine functions and the entire cycle are digitally controlled. The machine is validatable, making it suitable even for pharmaceutical applications.

The developed Hacona BI-type dedicated machine is unique in its industry. To formulate our development objectives, we meticulously gathered user needs and data from our existing customer base, who are market leaders within their industries worldwide.

Over the past 25 years, Hacona Ltd. has sold over 80,000 machines globally to more than 65 countries. More than 99% of our production is sold in export markets.

All our products are Hungarian-designed and manufactured. We are confident that our new Hacona BI-type dedicated machine will fully satisfy customer needs and further strengthen our leading position in international markets that we have achieved through dedication and innovation.