Featured Project

Hacona BI-type

Hacona BI-type high-performance industrial vacuum sealing machine is used for safe, large-scale packaging of foodstuffs, industrial materials, chemicals, and pharmaceutical ingredients. It can even be applied directly to packaging raw food industry materials.

The machine employs modified atmosphere packaging technology, providing the ideal environment within the film for the packaged material, achieved through vacuum and gas flushing.

My Tasks

Comprehensive mechanical design: concept planning, development, dimensioning, simulations, pneumatic planning.

Projects

Previous works

Complete machine designs of these projects were made by me in cooperation with affected electrical engineers and mechanics according to my clients demands. If you’re interested in more details, please contact me, and let’s discuss them in person. (Pictures are illustrations due to data protection issues.)

- designing several grippers on one robot head which can handle different types of electric units

- forwarding electric units from one station to another

- avoiding damage of the units and ensuring precise end position with the grippers

- staying clear of all possible collisions

- integrating affected electric and pneumatic units into the robot head

- working out the energy chain of electric cables and pneumatic pipes

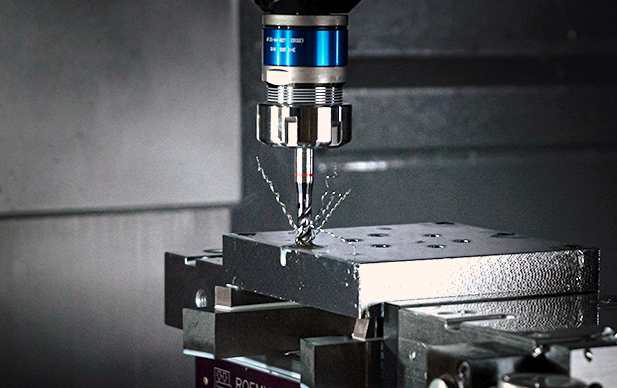

- workpiece: cast aluminium housing of an electric motor

- automation task: pre-drilling and tapping of several holes on the housing in a full-automated process (only changing the workpiece is made by operator)

- working out type changing method with customised fixtures for every type of housings

- ensuring possibility of tool change for machining holes with different diameters and thread sizes

- moving machining unit on linear slides vertically

- attaining feeding of workpiece with linear movement

- rotating workpiece by 90 degrees

- preventing units of the machine from flooding in case of using cooling fluid

- ensuring diversion of cooling fluid and chip

- ensuring fixed position of vehicle body elements and the ability of attaching to each other during automated welding process

- designing fixing and centering units

- avoiding possible collisions when body-element-assembler robots taking workpiece in and out

- making the fixture suitable for different types of body elements

12+

Years

Working

Experience

Working

Experience

My specialization

Mechanical Design of automated manufacturing equipments

Conception

Getting acquainted with all the details of a special manufacturing task defined by the client, which need to be automated in a production process.

Working out ideas of how a machine could execute the task and figuring out which is the best way for our case.

Mechanical design

Creating detailed 3D modell of the machine, which can “work” in the virtual world. Its mechanical modules are made of customised mechanical parts and the most suitable commercial parts. They’re also fitted to its pneumatic and electric parts, and all together can execute the defined task automated.

Documentation

Making complete, ‘ready-to-manufacture’ documentation of customised mechanical parts. Defining commercial mechanical, pneumatic and electric parts properly and listing them. Creating detailed assembly drawings of the machine helping to build it and find its parts later easily.

Optimization

Taking care of the budget. Designing customised parts so they can be manufactured as easy and as cost-effective as possible. Choosing the most suitable commercial parts and not the most expensive ones.

Keeping an eye also on usability: not to make mechanics’ life too hard when they build or use the machine.

As a freelancer

It gives me much pleasure to accomplish more and more projects for my clients with success.

0

Complete

projects for

projects for

0

Satisfied

Customers

Customers

I’m using leading engineering design tools in my work.

I’m working in my own office on my own computer, using softwares with my own licences.

Solid Edge

0%

Solidworks

0%

My Experience

2019-

Freelance

Mechanical Design

Engineer

Working out mechanical solutions for automation tasks. Making complete design and documentation of manufacturing machines executing several kinds of automated processes like welding, drilling, threading, cleaning etc.

2017-2019

ARH Inc.

Machine / Robot cell Designer

Creating production processes of automated robot cells assembling ID card readers and cameras. Designing and building complete machine modules from feeding and screwing to gripping etc.

2011-2017

Continental

Automotive

Hungary

Process

Engineer

Fully responsible for automated manufacturing machines in serial production of electronic parts. Developing equipments for highest performance. Specification of new machines and creating them with suppliers in Hungary and Germany.

Testimonials from my best clients

Ákos has excellent skills. He has designed a complete production cell for our company, which has significantly increased our efficiency. He is precise, punctual and extremely creative, which has made our cooperation much easier. I am sure that we will work together again in the future.

I would highly recommend him, even for more complex and complicated tasks!

Ákos has a strong value- and result-driven attitude, combined with a really up to date technological knowledge. ... He easily understood all the multi-national costumer demands and perform all the special requests, supporting the whole process with advanced technical solutions.

Our partnership is still running fluently, so I can strongly recommend him!

I have worked with Ákos on several automation projects as a mechanical design engineer. His work was high quality and fast. The cooperation was fair and smooth. He brought very good ideas and cost effective solutions. In the future, if I need a combi robot gripper or some other automation thing for any of my projects, I will be happy to contact Ákos with the task, as I have a very good customer experience with his service.

This year I had the pleasure working on a mechanical design tasks in a big automation project with Ákos.

Our team had to hire multiple external designers because of the size of the job, and Ákos was clearly standing out as the most helpful, most skilled, most flexible one.

I highly recommend his expertise in the area of custom built, complex machine design, but I am sure he will excel in other territories of mechanical design as well.

Beside his professional skills he has a great attitude towards problems to be solved and he was really easy to work with.

Contact

Please feel free to contact me! I’m usually available from 10:00-19:00 on weekdays.